Чеканка

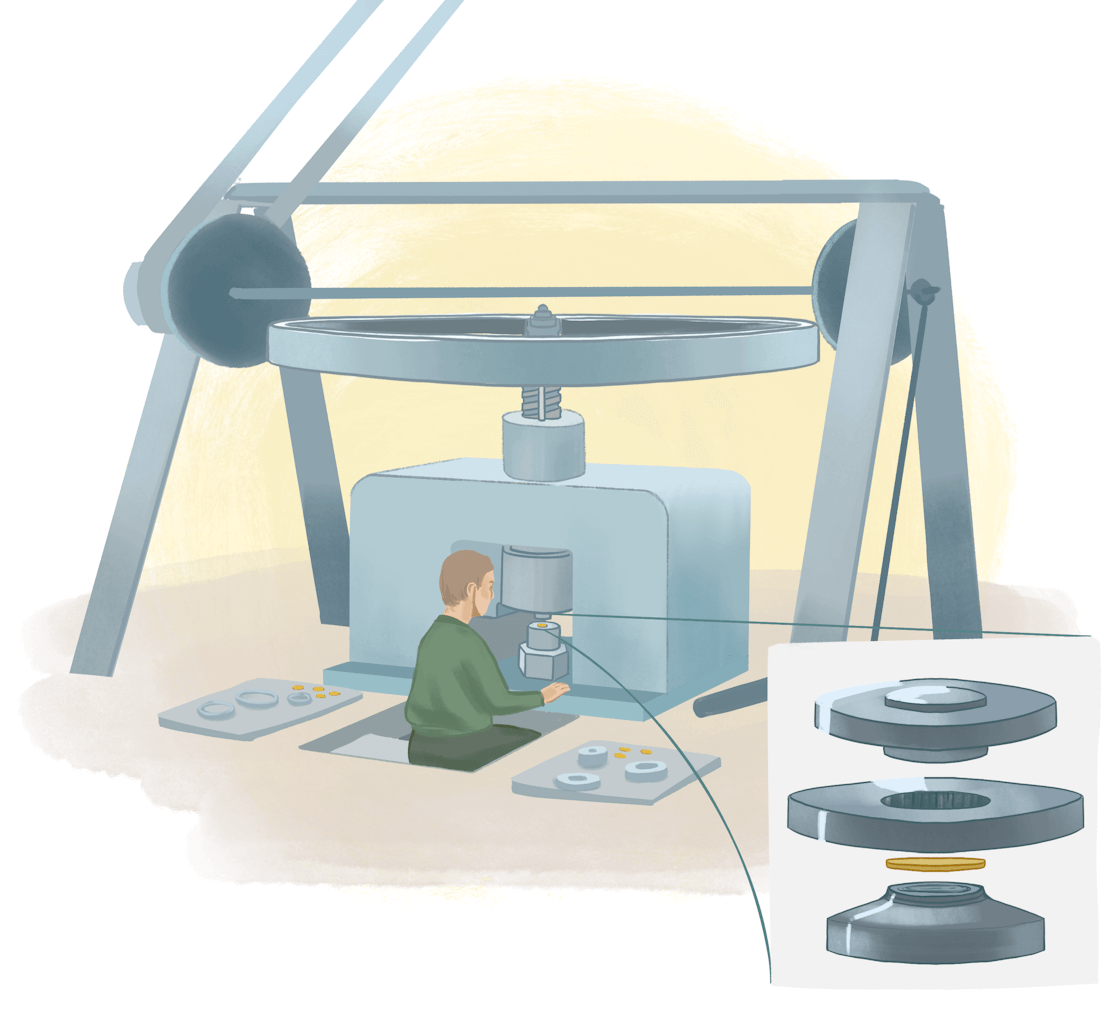

(en) A metallic planchet of the desired size and weight is prepared. This planchet is then placed on a fixed lower die (usually the obverse one), on which a mobile upper die (the reverse one) strikes. Thus, each die, which contains an inverse version of the images to be struck on the coin, impresses its mark simultaneously on the obverse and the reverse of the planchet.

This technique was invented in Europe in the middle of the 16th century, and gradually replaced the ancestral manual hammering technique. First operated by a leadscrew on a threaded nut, monetary presses continued to improve their output thanks first to steam levers from the 19th century, then thanks to electricity in the 20th century; a modern press can reach a production capacity of 800 coins/minute.

In addition to the increased productivity, this technique allows for very clear and regular reliefs, and the development in parallel of the use of a ferrule (a steel ring which prevents the blank from deforming during striking) allows perfectly round pieces with a smooth or engraved edge, preventing clipping.

This technique was invented in Europe in the middle of the 16th century, and gradually replaced the ancestral manual hammering technique. First operated by a leadscrew on a threaded nut, monetary presses continued to improve their output thanks first to steam levers from the 19th century, then thanks to electricity in the 20th century; a modern press can reach a production capacity of 800 coins/minute.

In addition to the increased productivity, this technique allows for very clear and regular reliefs, and the development in parallel of the use of a ferrule (a steel ring which prevents the blank from deforming during striking) allows perfectly round pieces with a smooth or engraved edge, preventing clipping.